How the Design of Blister Packs Affects Product Shelf Life and Consumer Appeal

Today, blister packs are widely used in the pharmaceutical sector thanks to the opportunities which have been created due to the ability to maintain product quality, its safe usage and aesthetic appeal. Concerning the packaging configuration, it is evident that the design of blister packs avails robust protection to tablets and capsules’ shelf life, and at the same time, responds to consumers’ expectations of the easy to use and attractive packaging. Through proper design of these packs, and in consideration to the new production techniques, the life of these products, therefore the satisfaction of the customers is assured. In this article we will be discussing how the blister pack designs impacts product shelf life and its attractiveness to the customers The application of technologies such as the tablet maker and pill maker machine.

The Role of Blister Packs in Product Shelf Life

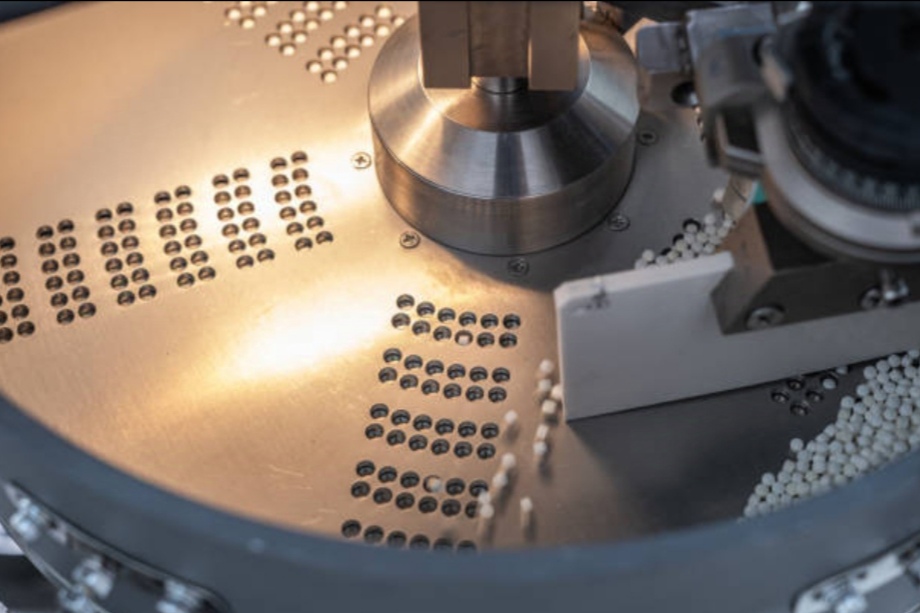

Blister packs are particularly engineered to shield tablets and capsules from normal environmental conditions that may otherwise cause the product to deteriorate. Among a number of factors, moisture, oxygen, light exposure and mechanical damage are considered most dangerous for pharmaceutical products’ stability and activity. They pierce these compartments separately on the same pocket and by forming a hermetic and rather robust shell around the drug, blister packs mean that these negative influences do not impact the medication, which should remain as viable as intended up to its shelf life. Furthermore, each specific tablet or capsule in blister packs are covered separately which reduces the likelihood of contaminants transferring between doses and where a dose is taken, it will not be exposed to air or humidity in the pack. This segmentation is vital, especially for drugs that barely endure changes in the environment or conditions in which the drug has to remain potent. By tablet maker technologies, manufacturers are able to be very precise in packaging where each tablet is individually placed in its enclosure. This attention to detail is also an added security measure in preserving the medication, and is also a demonstration of how the design of blister packs complements actual functional aspects of pharmaceutical manufacturing to maintain product quality and integrity.

Improving Blister Packs’ Aesthetics

Still, blister packs are not just a protection of the good; they are an intermediate between the good and the purchaser. The overall objective therefore, of a good blister packaging is to improve the consumer experience, by being convenient, easy to understand and aesthetically appealing. Convenience is important for the buyer, where the packaging should format allows for easy and smooth pop of tablets or capsules without compromising the product’s quality. Additional functional elements of blister packs are perforations for each compartment or the use of a push-through foil backing. Apart from the practical utility of having packs designed in this particular way, looks and appearance of blister packs are crucial when it comes to catching the attention of consumers. Those parts of the packaging that show the product inside help to build confidence and trust while bold logos and colors, as well as typography, will help the product be noticed in a pharmacy. They make first impression or impression that has strong influence on customers to but again and again the blister packs must be well designed and easy to handle. Combining these design elements with technologies for instance the pill maker machines makes it possible to achieve designs consistently and of high quality thus complimenting the image and brand identity to consumers.

Sustainability and Its Influence on Design

Currently, there is a heightened concern on the environment and pharmaceutical industries do pay much attention to sustainability in blister packs. The conventional materials in forming blister packs are PVC and aluminum, notwithstanding the fact that they are remarkable in their capability to guard the products inside them, they cause immense harm to the environment. To this end, some manufactures are resorting to using items like biodegradable plastics and recyclable materials that offer the same level of protection as blister packs. Robust packs for burstal handing are not only functional considering the established blister pack design but also have the outline of green consumerism. Consumers today have become more aware of the environment and therefore will prefer to buy products from firms that have adopted sustainable packaging. Moreover, utilization of sustainable materials is not an issue for implementing state of the art production technologies. New materials and the latest options available in the market of tablet maker and the mixin pill maker machine also called high sheeter machine can be adjusted in a way that the companies producing the pills perform to the highest standards and adopt a green means without much hindrance to its various production formulas. The change in blister pack designs for the more sustainable design seems to be in tow with the trend that has taken over the manufacturing world where companies are advised to strike sustainable noggins.

The Future of Blister Pack Design in Pharmaceutical Packaging

Currently, blister pack design is an ever-changing factor because of the exposure to new technologies and change in consumers’ preferences. There will also be enhancements of smart characteristics of pharmaceutical packaging that will contain factors like sensors of storage conditions as well as feed the results back to the consumer directly. These innovations can for example inform the user that the product has been subjected to undesirable conditions, to preserve the effectiveness of the medicine. Both the structure and materials science are also being improved through dedicated studies to new generation structures which should be ultra-durable, ultra-lightweight and environment friendly when offering protection while at the same time reducing wastage. In blister pack production, there will be enhancement of automation wherein tablet maker and pill maker machines will deliver a faster rate and the right accuracy. These systems will also enable further flexibility in catering to the many needs of the pharmaceutical market while preserving efficiency at a high level. Additional features like information through QR codes, using smart packaging for halting consumption after certain amount of consumption is achieved can be placed in the package as enhancements to consumer experience. In the course of the industry’s adoption of these innovations, blister pack design will be even more crucial in assuring product quality, sustainability, and consumer satisfaction.

Conclusion

The present configuration of the packs plays a major role not only in product protection, particularly with regard to the shelf life of tablets and capsules but also in attracting customers. It is therefore significant that the environment surrounding the medication is controlled and that the user’s experience is eased by the use of blister packs. Modern tablet maker and pill maker machine systems are used to make perfect blister packs, adhering to functionality as well as style. Since sustainability and smart packaging have just started to become trends, the future of blister pack design will follow the trend of adopting environmentally friendly materials as well as new features that are welcoming to current consumers. Implementing these improvements, the pharmaceutical manufacturers can produce the quality products that would easily satisfy the requirements of the pertinent legislation and the demands of the consumers; thus, the pharmaceutical manufacturers can successfully adapt themselves to the changes of the market.

Read More: The Future of Automotive Films: Insights from a Leading Window Tint Factory